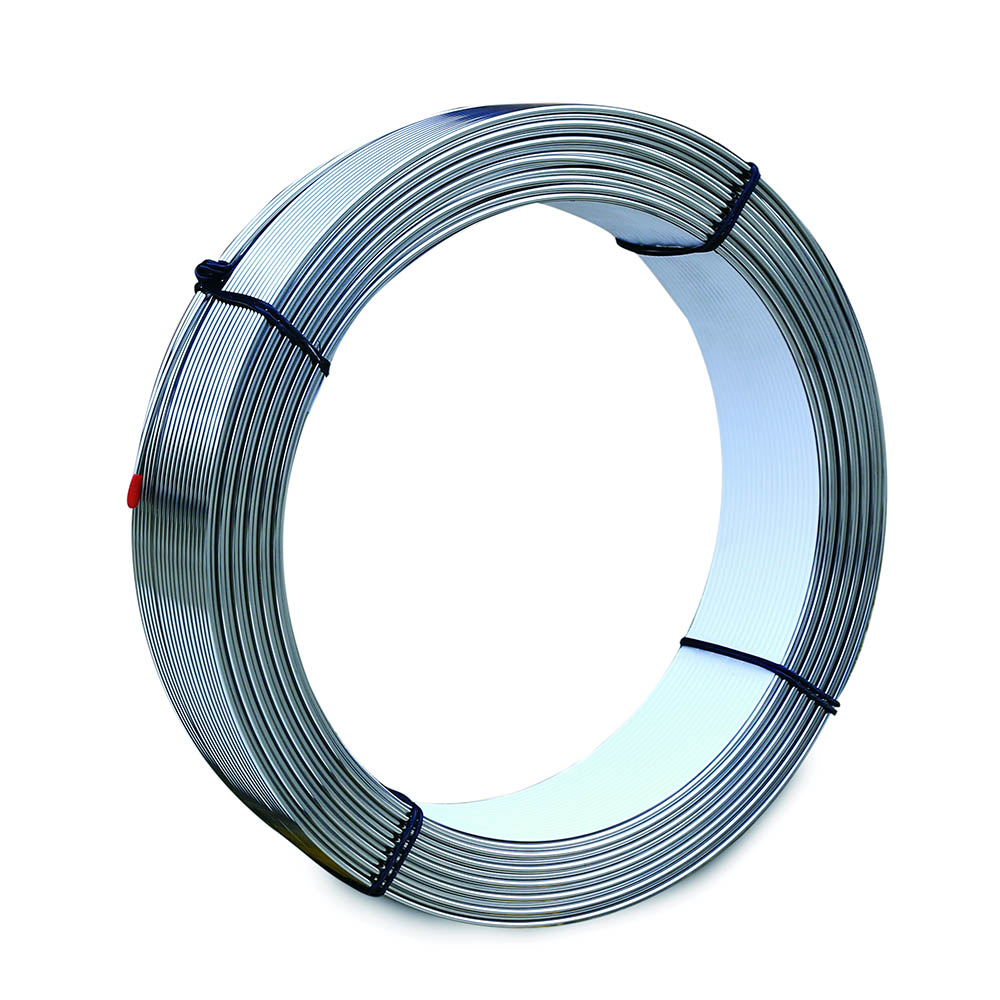

2022 High quality 44 Lb Welding Wire Spool - JQ.MH00Cr24Ni13 stainless steel submerged-arc welding wire – Jinqiao

2022 High quality 44 Lb Welding Wire Spool - JQ.MH00Cr24Ni13 stainless steel submerged-arc welding wire – Jinqiao Detail:

Features

Compared with manual welding, the deposition speed can be increased by 2-4 times, and the deposition efficiency is as high as 90%.

The adaptability of current and voltage is large, the setting of welding conditions is easy, and it is easy to carry out semi-automatic and automatic welding.

Good slag removal and glossy weld bead surface. In addition, there is little splash, the arc stability is excellent, and the X-ray is qualified.

Welding wire chemical composition(Wt%)

|

Model |

Welding wire chemical composition(Wt%) |

||||||||

|

C |

Mn |

Si |

Cr |

Ni |

P |

S |

Cu |

other |

|

|

JQ.MH00Cr24Ni13 |

0.026 |

1.74 |

0.58 |

23.49 |

12.9 |

0.024 |

0.008 |

- |

- |

Product performance

|

Compliant (equivalent) standard model |

An example of physical properties of deposited metal (with SJ601) |

||

|

GB |

AWS |

Tensile StrengthMPa |

Elongation% |

|

F309L-H00Cr24Ni13 |

ER309L |

558 |

40.0 |

Product welding reference current(AC or DC+)

|

Diameter(mm) |

¢2.5 |

¢3.2 |

¢4.0 |

¢5.0 |

|

Welding current(A) |

400-500 |

450-550 |

500-600 |

550-650 |

Product Specifications

|

Wire diameter |

¢2.5 |

¢3.2 |

¢4.0 |

¢5.0 |

|

Package weight |

25/50/100/200/250/300/350Kg/piece |

|||

Precautions for product use

1. The temperature between welds is recommended to be controlled at about 150°C. When multi-pass multi-layer welding of small and medium-sized specifications, pay attention to controlling the welding line energy.

2. The rust layer, moisture, oil, dust, etc. of the welding part must be cleaned up.

3. The flux must be baked at 300-350℃ for 2h before use.

The above suggestions are for reference only, and the actual situation shall prevail in the specific operation. If necessary, process qualification should be carried out before determining the welding plan.

Product detail pictures:

Related Product Guide:

With our loaded practical experience and thoughtful solutions, we now have been identified for a trusted provider for numerous intercontinental consumers for 2022 High quality 44 Lb Welding Wire Spool - JQ.MH00Cr24Ni13 stainless steel submerged-arc welding wire – Jinqiao , The product will supply to all over the world, such as: Swaziland, Japan, San Francisco, We've been adhering to the philosophy of "attracting customers with the best items and excellent service". We welcome customers, business associations and friends from all parts of the world to contact us and seek cooperation for mutual benefits.

The manufacturer gave us a big discount under the premise of ensuring the quality of products, thank you very much, we will select this company again.