China OEM Stainless Steel Mig Wire 5kg - JQ.H0Cr21Ni10 Stainless steel gas shielded solid welding wire in barrel – Jinqiao

China OEM Stainless Steel Mig Wire 5kg - JQ.H0Cr21Ni10 Stainless steel gas shielded solid welding wire in barrel – Jinqiao Detail:

Application

Widely used in petrochemical, pressure vessel, food machinery, medical equipment, fertilizer equipment, textile machinery, nuclear reactor, etc., such as welding of 12Cr18Ni9 (SUS 302), 06Cr19Ni10 (SUS 304) and other materials.

Welding wire chemical composition(Wt%)

|

Model |

Welding wire chemical composition(Wt%) |

||||||||

|

|

C |

Mn |

Si |

Cr |

Ni |

Mo |

P |

S |

Cu |

|

JQ.H0Cr21Ni10 |

0.035 |

1.80 |

0.31 |

20.15 |

9.52 |

0.03 |

0.013 |

0.008 |

0.34 |

Product performance

|

Compliant (equivalent) standard model |

An example of physical properties of deposited metal (with SJ601) |

||

|

GB |

AWS |

Tensile StrengthMPa |

Elongation% |

|

S308 |

ER308 |

594 |

40.5 |

Product welding reference current(AC or DC+)

|

Wire diameter(mm) |

¢0.8 |

¢1.0 |

¢1.2 |

|

|

Welding current(A)

|

Flat welding, horizontal welding |

70-150 |

100-200 |

140-220 |

|

vertical welding |

50-120 |

80-150 |

120-180 |

|

|

Overhead welding |

50-120 |

80-150 |

160-200 |

|

Product Specifications

|

Wire diameter |

¢0.8 |

¢1.0 |

¢1.2 |

|

Package weight |

12.5Kg/piece |

15Kg/piece |

15Kg/piece |

Precautions for product use

1. Shielding gas: Pay attention to the purity of the shielding gas, and the recommended gas mixture ratio is Ar+1-3%O2.

2. Gas flow: 20-25L/min.

3. Dry elongation: 15-25mm.

4. Really remove the rust layer, moisture, oil, dust, etc. on the welding part.

5. During outdoor welding, when the wind speed is greater than 1.5m/s, windproof measures should be taken, and appropriate windproof measures must be taken to prevent the occurrence of blowholes.

The above suggestions are for reference only, and the actual situation shall prevail in the specific operation. If necessary, process qualification should be carried out before determining the welding plan.

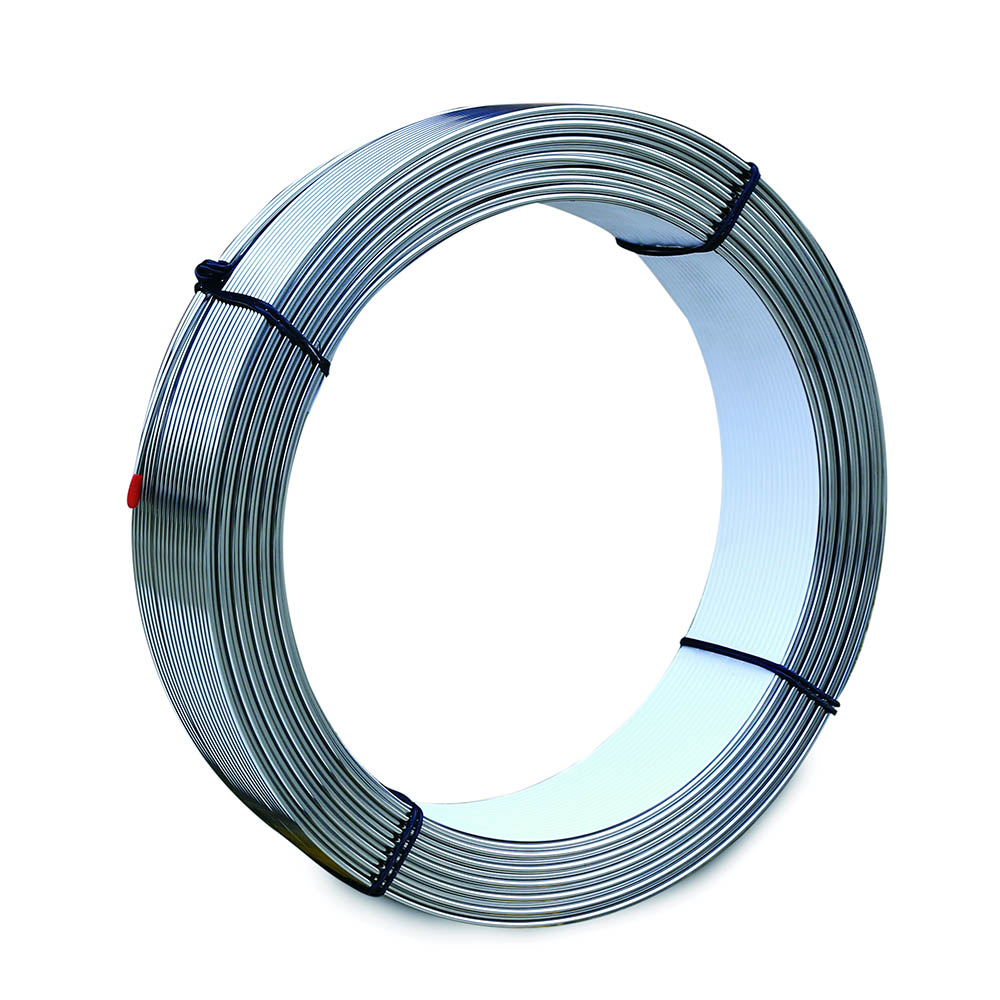

Product detail pictures:

Related Product Guide:

We stick to our enterprise spirit of "Quality, Efficiency, Innovation and Integrity". We aim to create more value for our customers with our rich resources, advanced machinery, experienced workers and excellent services for China OEM Stainless Steel Mig Wire 5kg - JQ.H0Cr21Ni10 Stainless steel gas shielded solid welding wire in barrel – Jinqiao , The product will supply to all over the world, such as: Porto, Lithuania, Brisbane, Due to our strict pursues in quality, and after-sale service, our product gets more and more popular around the world. Many clients came to visit our factory and place orders. And there are also many foreign friends who came for sight seeing, or entrust us to buy other stuff for them. You are most welcome to come to China, to our city and to our factory!

Products and services are very good, our leader is very satisfied with this procurement, it is better than we expected,