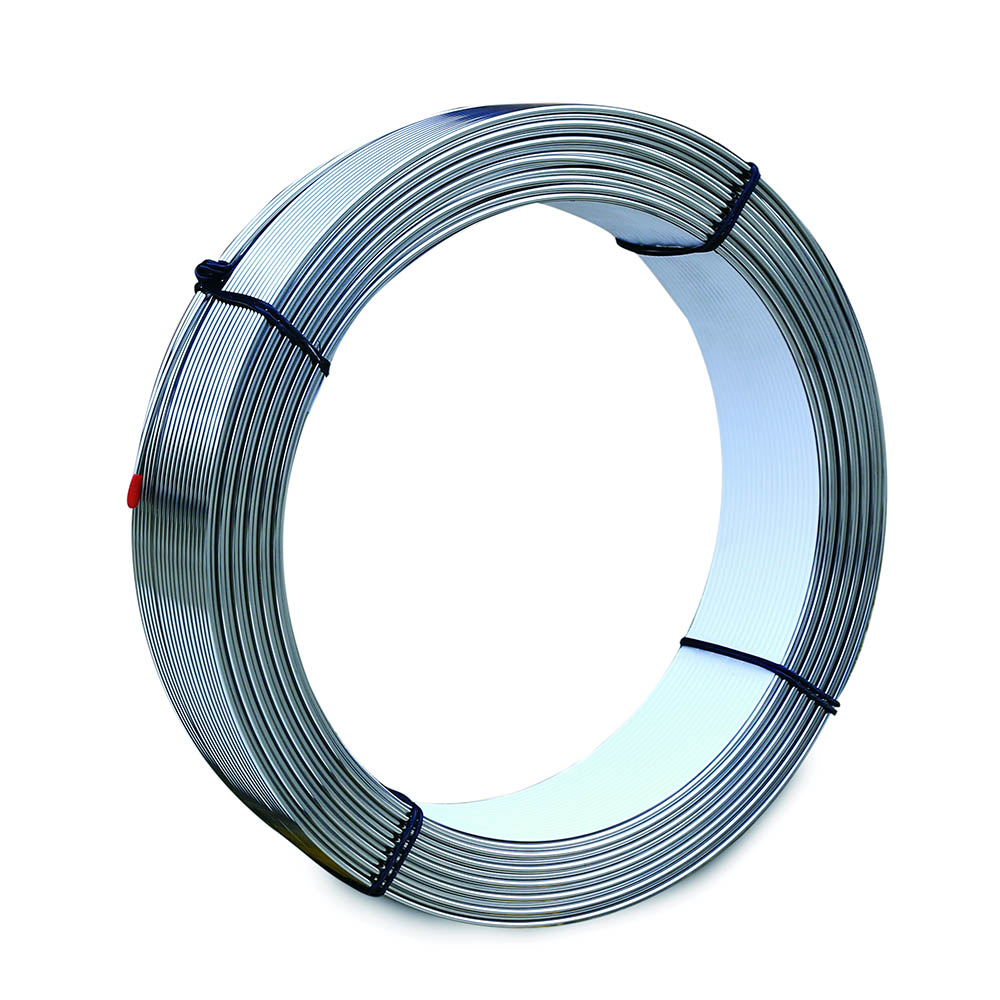

Excellent quality Flux Core Stainless Steel Mig Wire - JQ.H00Cr21Ni10T Stainless steel gas shielded solid welding wire in barrel – Jinqiao

Excellent quality Flux Core Stainless Steel Mig Wire - JQ.H00Cr21Ni10T Stainless steel gas shielded solid welding wire in barrel – Jinqiao Detail:

Application

Mainly for CNG (compressed natural gas), LNG (liquefied natural gas), LPG (liquefied petroleum gas) energy equipment field for welding stainless steel materials used in cryogenic and low temperature environments; such as 12Cr18Ni9 (SUS 302), 06Cr19Ni10 (SUS 304), 022Cr18Ni9 (SUS 304L) ) welding.

Welding wire chemical composition(Wt%)

|

Model |

Welding wire chemical composition(Wt%) |

||||||||

|

|

C |

Mn |

Si |

Cr |

Ni |

Mo |

P |

S |

Cu |

|

JQ.H00Cr21Ni10T |

0.023 |

1.63 |

0.40 |

20.12 |

10.35 |

0.03 |

0.013 |

0.009 |

0.16 |

Product performance

|

Compliant (equivalent) standard model |

An example of physical properties of deposited metal (with SJ601) |

||

|

GB |

AWS |

Tensile StrengthMPa |

Elongation% |

|

S308L |

ER308L |

563 |

39.5 |

Product welding reference current(AC or DC+)

|

Wire diameter(mm) |

¢0.8 |

¢1.0 |

¢1.2 |

|

|

Welding current(A) |

Flat welding, horizontal welding |

70-150 |

100-200 |

140-220 |

|

vertical welding |

50-120 |

80-150 |

120-180 |

|

|

Overhead welding |

50-120 |

80-150 |

160-200 |

|

Product Specifications

|

Wire diameter |

¢0.8 |

¢1.0 |

¢1.2 |

|

Package weight |

12.5Kg/piece |

15Kg/piece |

15Kg/piece |

Precautions for product use

1. Shielding gas: Pay attention to the purity of the shielding gas, and the recommended gas mixture ratio is Ar+1-3%O2.

2. Gas flow: 20-25L/min.

3. Dry elongation: 15-25mm.

4. Really remove the rust layer, moisture, oil, dust, etc. on the welding part.

5. During outdoor welding, when the wind speed is greater than 1.5m/s, windproof measures should be taken, and appropriate windproof measures must be taken to prevent the occurrence of blowholes.

The above suggestions are for reference only, and the actual situation shall prevail in the specific operation. If necessary, process qualification should be carried out before determining the welding plan.

Product detail pictures:

Related Product Guide:

Having a positive and progressive attitude to customer's fascination, our organization constantly improves our solution high-quality to fulfill the requirements of shoppers and further focuses on safety, reliability, environmental prerequisites, and innovation of Excellent quality Flux Core Stainless Steel Mig Wire - JQ.H00Cr21Ni10T Stainless steel gas shielded solid welding wire in barrel – Jinqiao , The product will supply to all over the world, such as: Manila, Zimbabwe, Durban, We have constructed strong and long co-operation relationship with an enormous quantity of companies within this business overseas. Immediate and specialist after-sale service supplied by our consultant group has happy our buyers. Detailed Info and parameters from the merchandise will probably be sent to you for any thorough acknowledge. Free samples may be delivered and company check out to our corporation. n Portugal for negotiation is constantly welcome. Hope to get inquiries type you and construct a long-term co-operation partnership.

Timely delivery, strict implementation of the contract provisions of the goods, encountered special circumstances, but also actively cooperate, a trustworthy company!