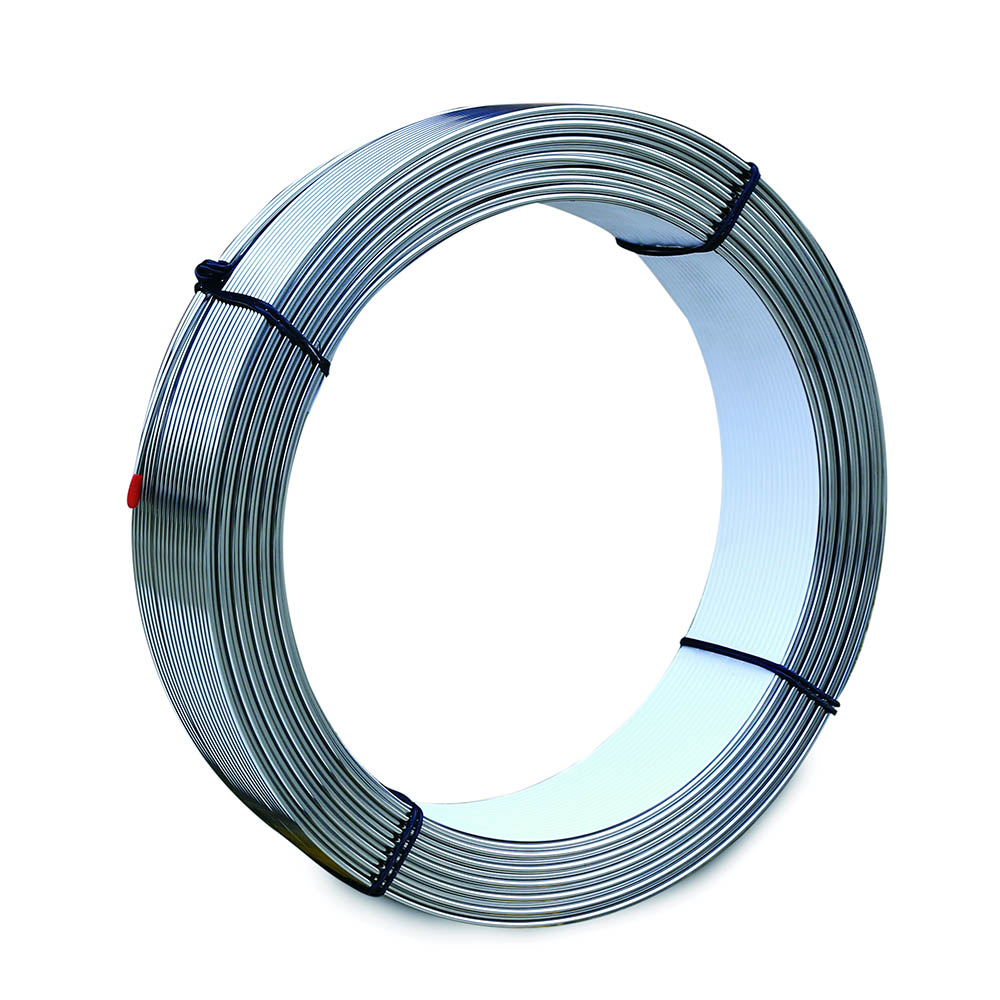

Factory For Flux Core Welding Machine - JQ.H0Cr21Ni10 Stainless steel gas shielded solid welding wire in barrel – Jinqiao

Factory For Flux Core Welding Machine - JQ.H0Cr21Ni10 Stainless steel gas shielded solid welding wire in barrel – Jinqiao Detail:

Application

Widely used in petrochemical, pressure vessel, food machinery, medical equipment, fertilizer equipment, textile machinery, nuclear reactor, etc., such as welding of 12Cr18Ni9 (SUS 302), 06Cr19Ni10 (SUS 304) and other materials.

Welding wire chemical composition(Wt%)

|

Model |

Welding wire chemical composition(Wt%) |

||||||||

|

|

C |

Mn |

Si |

Cr |

Ni |

Mo |

P |

S |

Cu |

|

JQ.H0Cr21Ni10 |

0.035 |

1.80 |

0.31 |

20.15 |

9.52 |

0.03 |

0.013 |

0.008 |

0.34 |

Product performance

|

Compliant (equivalent) standard model |

An example of physical properties of deposited metal (with SJ601) |

||

|

GB |

AWS |

Tensile StrengthMPa |

Elongation% |

|

S308 |

ER308 |

594 |

40.5 |

Product welding reference current(AC or DC+)

|

Wire diameter(mm) |

¢0.8 |

¢1.0 |

¢1.2 |

|

|

Welding current(A)

|

Flat welding, horizontal welding |

70-150 |

100-200 |

140-220 |

|

vertical welding |

50-120 |

80-150 |

120-180 |

|

|

Overhead welding |

50-120 |

80-150 |

160-200 |

|

Product Specifications

|

Wire diameter |

¢0.8 |

¢1.0 |

¢1.2 |

|

Package weight |

12.5Kg/piece |

15Kg/piece |

15Kg/piece |

Precautions for product use

1. Shielding gas: Pay attention to the purity of the shielding gas, and the recommended gas mixture ratio is Ar+1-3%O2.

2. Gas flow: 20-25L/min.

3. Dry elongation: 15-25mm.

4. Really remove the rust layer, moisture, oil, dust, etc. on the welding part.

5. During outdoor welding, when the wind speed is greater than 1.5m/s, windproof measures should be taken, and appropriate windproof measures must be taken to prevent the occurrence of blowholes.

The above suggestions are for reference only, and the actual situation shall prevail in the specific operation. If necessary, process qualification should be carried out before determining the welding plan.

Product detail pictures:

Related Product Guide:

Our solutions are widely recognized and trusted by consumers and will meet up with constantly developing financial and social requires for Factory For Flux Core Welding Machine - JQ.H0Cr21Ni10 Stainless steel gas shielded solid welding wire in barrel – Jinqiao , The product will supply to all over the world, such as: Mali, Manchester, Barcelona, With the technology as the core, develop and produce high-quality products according to the diverse needs of the market. With this concept,the company will continue to develop products with high added values and continuously improve products,and will provide many customers with the best products and services!

This company has a lot of ready-made options to choose and also could custom new program according to our demand, which is very nice to meet our needs.