Factory Supply Welding Material Suppliers - JQ.H1Cr24Ni13 Stainless steel gas shielded solid welding wire in barrel – Jinqiao

Factory Supply Welding Material Suppliers - JQ.H1Cr24Ni13 Stainless steel gas shielded solid welding wire in barrel – Jinqiao Detail:

Application

It is often used in the welding of carbon steel and stainless steel dissimilar materials or in the welding of martensitic and pearlitic stainless steels with poor toughness. Applications such as petrochemical, thermal power plants and other industries.

Welding wire chemical composition(Wt%)

|

Model |

Welding wire chemical composition(Wt%) |

||||||||

|

|

C |

Mn |

Si |

Cr |

Ni |

Mo |

P |

S |

Cu |

|

JQ.H1Cr24Ni13 |

0.081 |

1.61 |

0.40 |

23.85 |

13.15 |

0.02 |

0.012 |

0.013 |

0.23 |

Product performance

|

Compliant (equivalent) standard model |

An example of physical properties of deposited metal (with SJ601) |

||

|

GB |

AWS |

Tensile StrengthMPa |

Elongation% |

|

S309 |

ER309 |

594 |

41.5 |

Product welding reference current(AC or DC+)

|

Wire diameter(mm) |

¢0.8 |

¢1.0 |

¢1.2 |

|

|

Welding current(A) |

Flat welding, horizontal welding |

70-150 |

100-200 |

140-220 |

|

vertical welding |

50-120 |

80-150 |

120-180 |

|

|

Overhead welding |

50-120 |

80-150 |

160-200 |

|

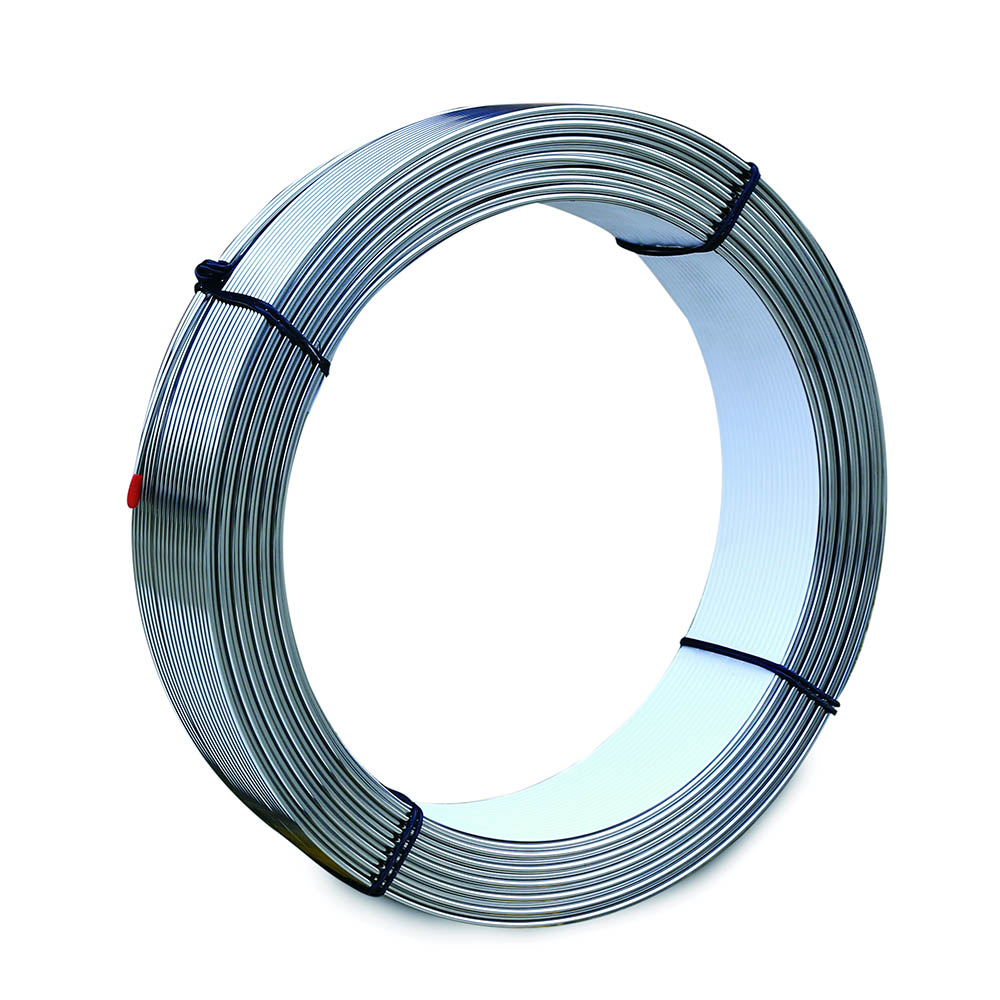

Product Specifications

|

Wire diameter |

¢0.8 |

¢1.0 |

¢1.2 |

|

Package weight |

12.5Kg/piece |

15Kg/piece |

15Kg/piece |

Precautions for product use

1. Shielding gas: Pay attention to the purity of the shielding gas, and the recommended gas mixture ratio is Ar+1-3%O2.

2. Gas flow: 20-25L/min.

3. Dry elongation: 15-25mm.

4. Really remove the rust layer, moisture, oil, dust, etc. on the welding part.

5. During outdoor welding, when the wind speed is greater than 1.5m/s, windproof measures should be taken, and appropriate windproof measures must be taken to prevent the occurrence of blowholes.

The above suggestions are for reference only, and the actual situation shall prevail in the specific operation. If necessary, process qualification should be carried out before determining the welding plan.

Product detail pictures:

Related Product Guide:

"Based on domestic market and expand overseas business" is our development strategy for Factory Supply Welding Material Suppliers - JQ.H1Cr24Ni13 Stainless steel gas shielded solid welding wire in barrel – Jinqiao , The product will supply to all over the world, such as: Bahamas, Sweden, New Delhi, With good quality, reasonable price and sincere service, we enjoy a good reputation. Products are exported to South America, Australia, Southeast Asia and so on. Warmly welcome customers at home and abroad to cooperate with us for the brilliant future.

We have been looking for a professional and responsible supplier, and now we find it.