Good User Reputation for 0.6 Mm Mig Welding Wire - JQ.MH1Cr24Ni13 stainless steel submerged-arc welding wire – Jinqiao

Good User Reputation for 0.6 Mm Mig Welding Wire - JQ.MH1Cr24Ni13 stainless steel submerged-arc welding wire – Jinqiao Detail:

Application

It is often used in the welding of carbon steel and stainless steel dissimilar materials or in the welding of martensitic and pearlitic stainless steels with poor toughness. Applications such as petrochemical, thermal power plants and other industries.

Welding wire chemical composition(Wt%)

|

Model |

Welding wire chemical composition(Wt%) |

||||||||

|

C |

Mn |

Si |

Cr |

Ni |

P |

S |

Cu |

other |

|

|

JQ.MH1Cr24Ni13 |

0.051 |

1.79 |

0.56 |

23.84 |

13.10 |

0.024 |

0.012 |

0.13 |

Mo:0.20 |

Product performance

|

Compliant (equivalent) standard model |

An example of physical properties of deposited metal (with SJ601) |

||

|

GB |

AWS |

Tensile StrengthMPa |

Elongation% |

|

F309-H1Cr24Ni13 |

ER309 |

599 |

36.0 |

Product welding reference current(AC or DC+)

|

Diameter(mm) |

¢2.5 |

¢3.2 |

¢4.0 |

¢5.0 |

|

Welding current(A) |

400-500 |

450-550 |

500-600 |

550-650 |

Product Specifications

|

Wire diameter |

¢2.5 |

¢3.2 |

¢4.0 |

¢5.0 |

|

Package weight |

25/50/100/200/250/300/350Kg/piece |

|||

Precautions for product use

1. The temperature between welds is recommended to be controlled at about 150°C. When multi-pass multi-layer welding of small and medium-sized specifications, pay attention to controlling the welding line energy.

2. The rust layer, moisture, oil, dust, etc. of the welding part must be cleaned up.

3. The flux must be baked at 300-350℃ for 2h before use.

The above suggestions are for reference only, and the actual situation shall prevail in the specific operation. If necessary, process qualification should be carried out before determining the welding plan.

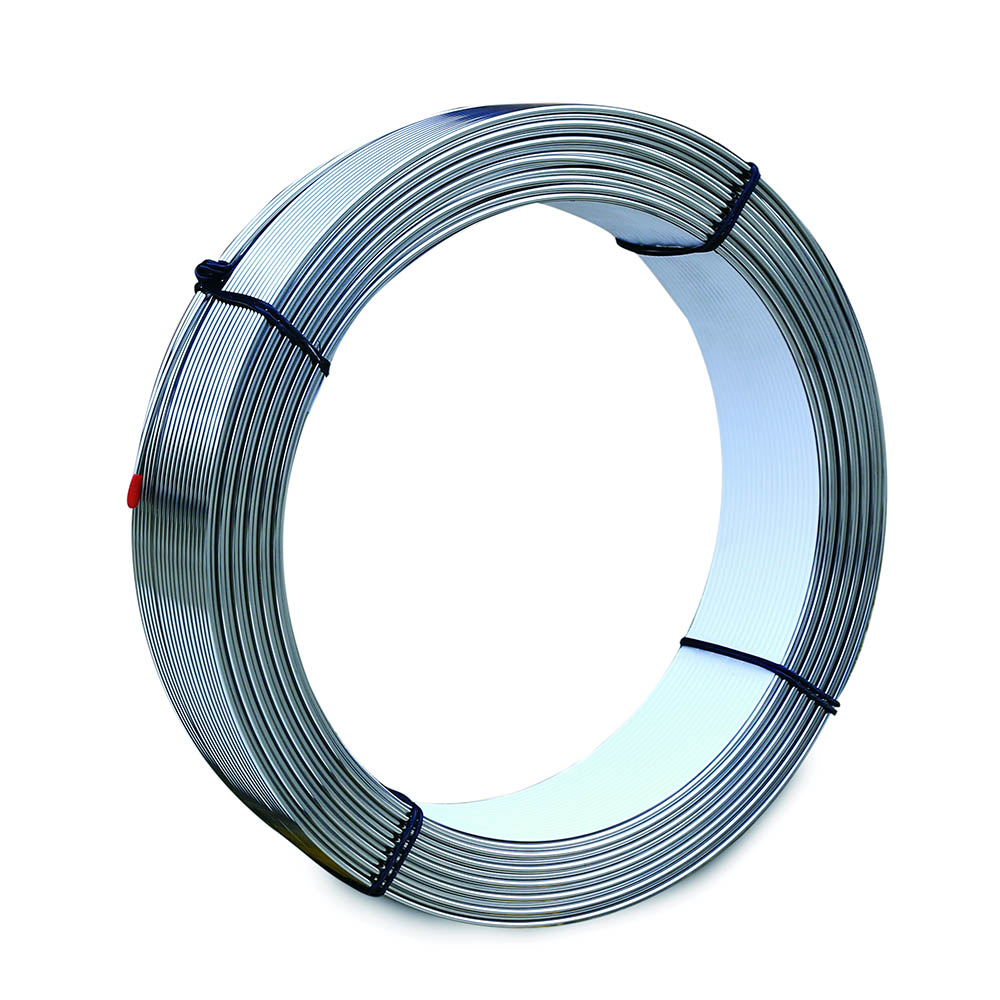

Product detail pictures:

Related Product Guide:

We follow our enterprise spirit of "Quality, Efficiency, Innovation and Integrity". We aim to create much more worth for our buyers with our abundant resources, highly developed machinery, experienced workers and great providers for Good User Reputation for 0.6 Mm Mig Welding Wire - JQ.MH1Cr24Ni13 stainless steel submerged-arc welding wire – Jinqiao , The product will supply to all over the world, such as: Albania, US, Paraguay, Our faith is to be honest first, so we just supply high quality products to our customers. Really hope that we can be business partners. We believe that we can establish long time business relationship with each other. You can contact us freely for more information and pricelist of our products ! You will be Unique with our hair products !!

We feel easy to cooperate with this company, the supplier is very responsible, thanks.There will be more in-depth cooperation.