High Quality for Stainless Wire For Mig Welder - JQ.H0Cr21Ni10 Stainless steel gas shielded solid welding wire in barrel – Jinqiao

High Quality for Stainless Wire For Mig Welder - JQ.H0Cr21Ni10 Stainless steel gas shielded solid welding wire in barrel – Jinqiao Detail:

Application

Widely used in petrochemical, pressure vessel, food machinery, medical equipment, fertilizer equipment, textile machinery, nuclear reactor, etc., such as welding of 12Cr18Ni9 (SUS 302), 06Cr19Ni10 (SUS 304) and other materials.

Welding wire chemical composition(Wt%)

|

Model |

Welding wire chemical composition (Wt%) |

|

||||||||

|

C |

Mn |

Si |

Cr |

Ni |

Mo |

P |

S |

Cu |

Other |

|

|

JQ.H0Cr21Ni10 |

0.035 |

1.80 |

0.31 |

20.15 |

9.52 |

0.03 |

0.013 |

0.008 |

0.34 |

- |

Product performance

|

Compliant (equivalent) standard model |

An example of physical properties of deposited metal (with SJ601) |

||

|

GB |

AWS |

Tensile StrengthMPa |

Elongation% |

|

S308 |

ER308 |

594 |

40.5 |

Product welding reference current(AC or DC+)

|

Wire diameter(mm) |

¢0.8 |

¢1.0 |

¢1.2 |

|

|

Welding current(A) |

Flat welding, horizontal welding |

70-150 |

100-200 |

140-220 |

|

vertical welding |

50-120 |

80-150 |

120-180 |

|

|

Overhead welding |

50-120 |

80-150 |

160-200 |

|

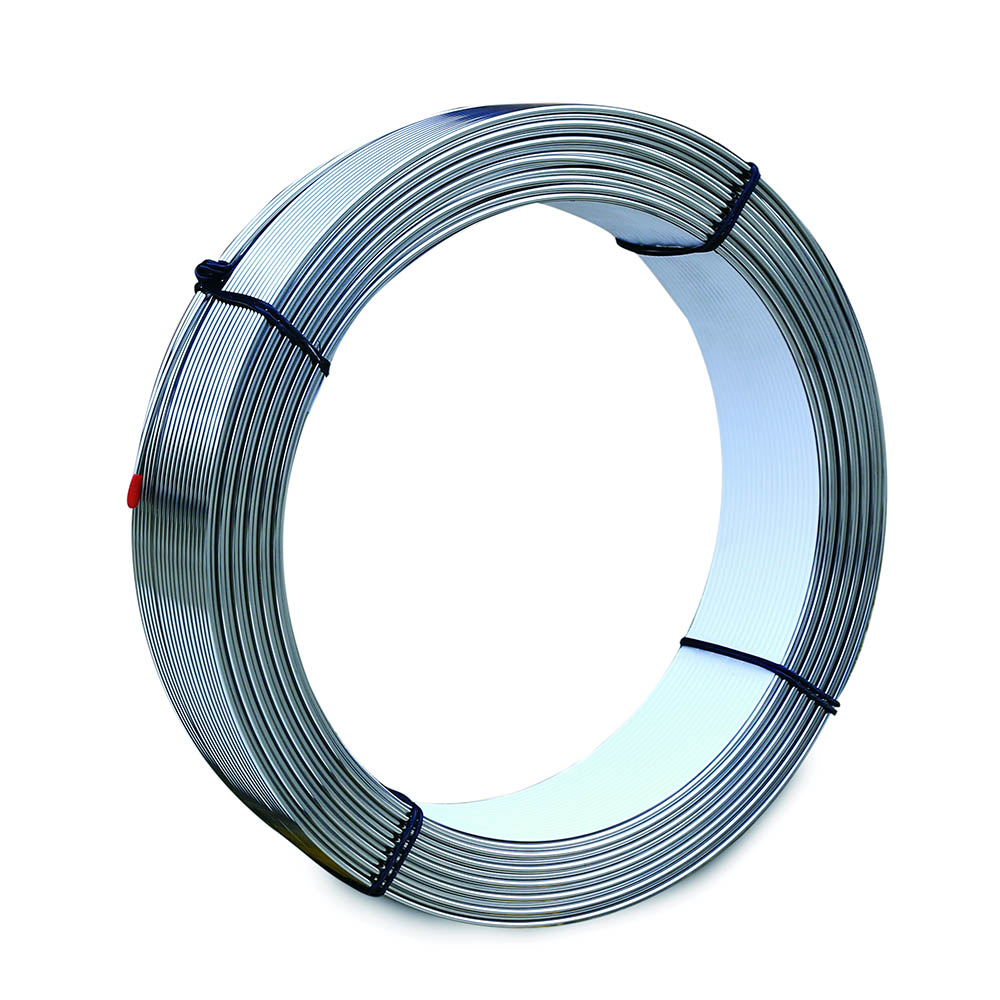

Product Specifications

|

Wire diameter |

¢0.8 |

¢1.0 |

¢1.2 |

|

Package weight |

12.5Kg/piece |

15Kg/piece |

15Kg/piece |

Precautions for product use

1. Shielding gas: Pay attention to the purity of the shielding gas, and the recommended gas mixture ratio is Ar+1-3%O2.

2. Gas flow: 20-25L/min.

3. Dry elongation: 15-25mm.

4. Really remove the rust layer, moisture, oil, dust, etc. on the welding part.

5. During outdoor welding, when the wind speed is greater than 1.5m/s, windproof measures should be taken, and appropriate windproof measures must be taken to prevent the occurrence of blowholes.

The above suggestions are for reference only, and the actual situation shall prevail in the specific operation. If necessary, process qualification should be carried out before determining the welding plan.

Product detail pictures:

Related Product Guide:

Our company has been concentrating on brand strategy. Customers' pleasure is our greatest advertising. We also source OEM service for High Quality for Stainless Wire For Mig Welder - JQ.H0Cr21Ni10 Stainless steel gas shielded solid welding wire in barrel – Jinqiao , The product will supply to all over the world, such as: Uruguay, Bogota, Seychelles, Qualified R&D engineer will be there for your consultation service and we will try our best to meet your requirements. So please feel free to contact us for inquiries. You'll be able to send us emails or call us for small business. Also you are able to come to our business by yourself to get further knowing of us. And we will surely give you the best quotation and after-sale service. We're ready to build stable and friendly relations with our merchants. To achieve mutual success, we will make our best efforts to build a solid co-operation and transparent communication work with our companions. Above all, we are here to welcome your inquiries for any of our goods and service.

Factory equipment is advanced in the industry and the product is fine workmanship, moreover the price is very cheap, value for money!