OEM Factory for Mig Welding Wire 0.8 Mm - JQ.MH00Cr21Ni10 stainless steel submerged-arc welding wire – Jinqiao

OEM Factory for Mig Welding Wire 0.8 Mm - JQ.MH00Cr21Ni10 stainless steel submerged-arc welding wire – Jinqiao Detail:

Application

Widely used in petrochemical and other industries, such as welding of 022Cr18Ni9 (SUS 304L) and other materials.

Welding wire chemical composition(Wt%)

|

Model |

Welding wire chemical composition(Wt%) |

||||||||

|

C |

Mn |

Si |

Cr |

Ni |

P |

S |

Cu |

other |

|

|

JQ.MH00Cr21Ni10 |

0.027 |

1.75 |

0.57 |

20.27 |

9.56 |

0.023 |

0.010 |

- |

- |

Product performance

|

Compliant (equivalent) standard model |

An example of physical properties of deposited metal (with SJ601) |

||

|

GB |

AWS |

Tensile StrengthMPa |

Elongation% |

|

F308L-H00Cr21Ni10 |

ER308L |

568 |

35.5 |

Product welding reference current(AC or DC+)

|

Diameter(mm) |

¢2.5 |

¢3.2 |

¢4.0 |

¢5.0 |

|

Welding current(A) |

400-500 |

450-550 |

500-600 |

550-650 |

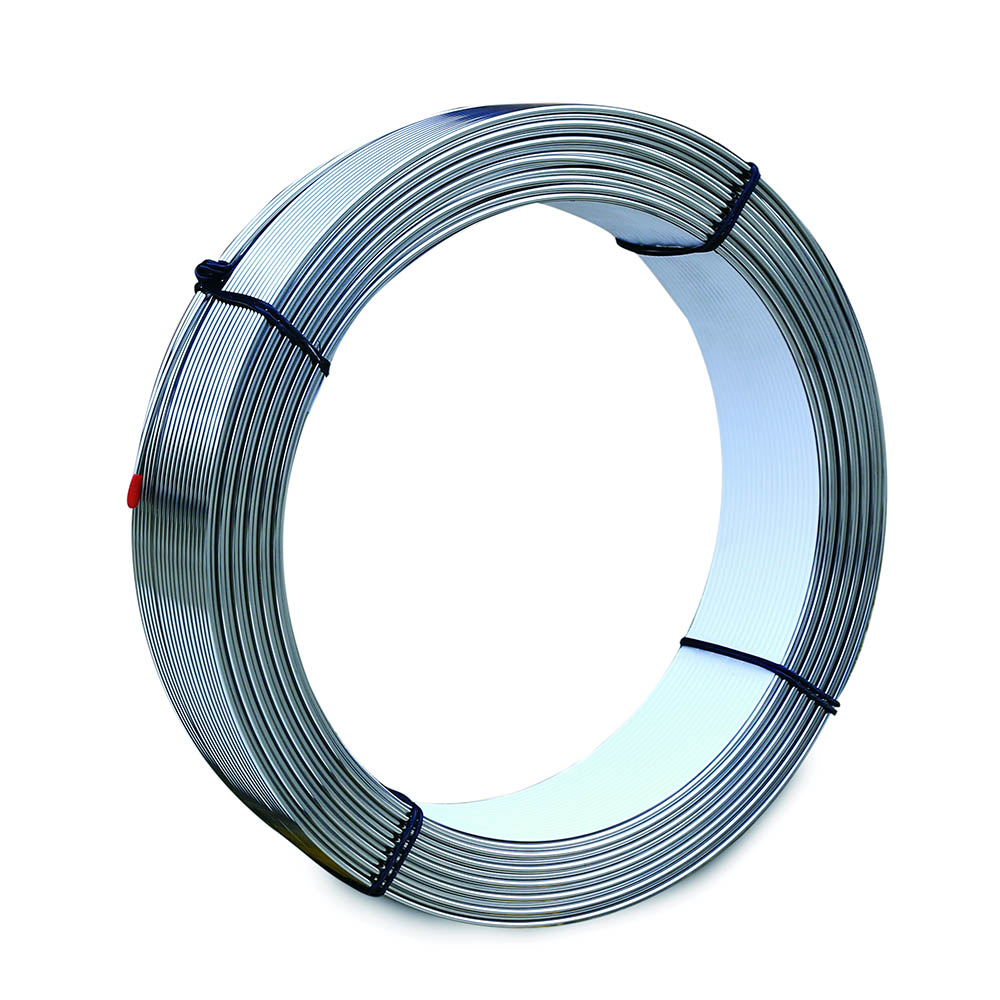

Product Specifications

|

Wire diameter |

¢2.5 |

¢3.2 |

¢4.0 |

¢5.0 |

|

Package weight |

25/50/100/200/250/300/350Kg/piece |

|||

Precautions for product use

1. The temperature between welds is recommended to be controlled at about 150°C. When multi-pass multi-layer welding of small and medium-sized specifications, pay attention to controlling the welding line energy.

2. The rust layer, moisture, oil, dust, etc. of the welding part must be cleaned up.

3. The flux must be baked at 300-350℃ for 2h before use.

The above suggestions are for reference only, and the actual situation shall prevail in the specific operation. If necessary, process qualification should be carried out before determining the welding plan.

Product detail pictures:

Related Product Guide:

Good quality To start with,and Purchaser Supreme is our guideline to offer the top service to our customers.Presently, we've been seeking our best to be amongst the top exporters inside our industry to fulfill consumers extra need to have for OEM Factory for Mig Welding Wire 0.8 Mm - JQ.MH00Cr21Ni10 stainless steel submerged-arc welding wire – Jinqiao , The product will supply to all over the world, such as: Bandung, United States, Plymouth, we have complete material production line, assembling line , quality control system, and the most importantly, we have many patents technology and experienced technical&production team, professional sales service team. With all those advantages, we are going to create"the reputable international brand of nylon monofilaments", and spreading our products to every corner of the world. We are keep moving and try our best to serve our customers.

Hope that the company could stick to the enterprise spirit of "Quality, Efficiency, Innovation and Integrity", it will be better and better in the future.