OEM/ODM China 70mm Welding Cable - JQ.H00Cr21Ni10T Stainless steel gas shielded solid welding wire in barrel – Jinqiao

OEM/ODM China 70mm Welding Cable - JQ.H00Cr21Ni10T Stainless steel gas shielded solid welding wire in barrel – Jinqiao Detail:

Application

Mainly for CNG (compressed natural gas), LNG (liquefied natural gas), LPG (liquefied petroleum gas) energy equipment field for welding stainless steel materials used in cryogenic and low temperature environments; such as 12Cr18Ni9 (SUS 302), 06Cr19Ni10 (SUS 304), 022Cr18Ni9 (SUS 304L) ) welding.

Welding wire chemical composition(Wt%)

|

Model |

Welding wire chemical composition(Wt%) |

||||||||

|

|

C |

Mn |

Si |

Cr |

Ni |

Mo |

P |

S |

Cu |

|

JQ.H00Cr21Ni10T |

0.023 |

1.63 |

0.40 |

20.12 |

10.35 |

0.03 |

0.013 |

0.009 |

0.16 |

Product performance

|

Compliant (equivalent) standard model |

An example of physical properties of deposited metal (with SJ601) |

||

|

GB |

AWS |

Tensile StrengthMPa |

Elongation% |

|

S308L |

ER308L |

563 |

39.5 |

Product welding reference current(AC or DC+)

|

Wire diameter(mm) |

¢0.8 |

¢1.0 |

¢1.2 |

|

|

Welding current(A) |

Flat welding, horizontal welding |

70-150 |

100-200 |

140-220 |

|

vertical welding |

50-120 |

80-150 |

120-180 |

|

|

Overhead welding |

50-120 |

80-150 |

160-200 |

|

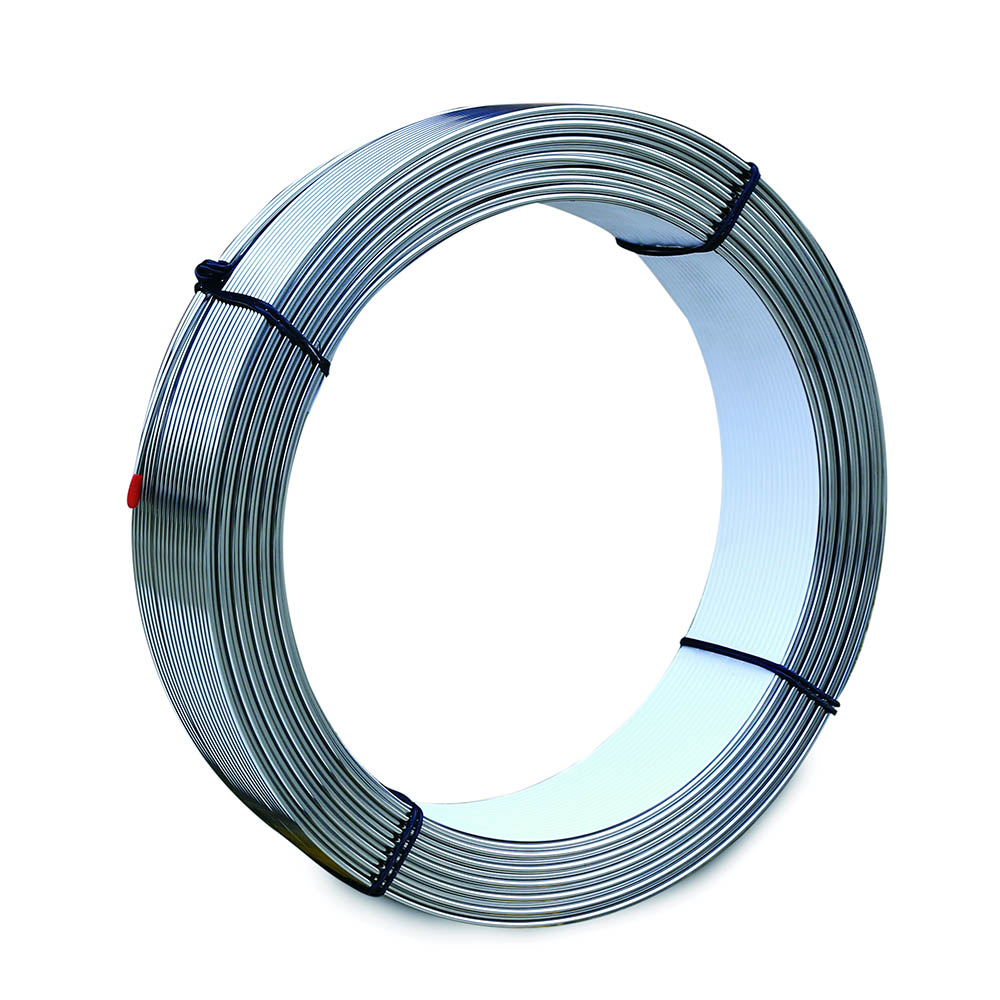

Product Specifications

|

Wire diameter |

¢0.8 |

¢1.0 |

¢1.2 |

|

Package weight |

12.5Kg/piece |

15Kg/piece |

15Kg/piece |

Precautions for product use

1. Shielding gas: Pay attention to the purity of the shielding gas, and the recommended gas mixture ratio is Ar+1-3%O2.

2. Gas flow: 20-25L/min.

3. Dry elongation: 15-25mm.

4. Really remove the rust layer, moisture, oil, dust, etc. on the welding part.

5. During outdoor welding, when the wind speed is greater than 1.5m/s, windproof measures should be taken, and appropriate windproof measures must be taken to prevent the occurrence of blowholes.

The above suggestions are for reference only, and the actual situation shall prevail in the specific operation. If necessary, process qualification should be carried out before determining the welding plan.

Product detail pictures:

Related Product Guide:

We keep on with our business spirit of "Quality, Performance, Innovation and Integrity". We goal to create much more worth for our customers with our rich resources, state-of-the-art machinery, experienced workers and exceptional providers for OEM/ODM China 70mm Welding Cable - JQ.H00Cr21Ni10T Stainless steel gas shielded solid welding wire in barrel – Jinqiao , The product will supply to all over the world, such as: Croatia, Honduras, Manila, Merchandise have been exported to Asia, Mid-east,European and Germany market. Our company has constantly been able to update the items performance and safety to meet the markets and strive to be top A on stable quality and sincere service. If you have the honor to do business with our company. we'll undoubtedly do our very best to support your business in China.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.