Good Quality Stainless Steel Submerged-Arc Welding Wire - JQ.MH00Cr21Ni10T stainless steel submerged-arc welding wire – Jinqiao

Good Quality Stainless Steel Submerged-Arc Welding Wire - JQ.MH00Cr21Ni10T stainless steel submerged-arc welding wire – Jinqiao Detail:

Application

Mainly for CNG (compressed natural gas), LNG (liquefied natural gas), LPG (liquefied petroleum gas) energy equipment field for welding stainless steel materials used in cryogenic and low temperature environments; such as 12Cr18Ni9 (SUS 302), 06Cr19Ni10 (SUS 304), 022Cr18Ni9 (SUS 304L) ) welding.

Welding wire chemical composition(Wt%)

|

Model |

Welding wire chemical composition(Wt%) |

||||||||

|

C |

Mn |

Si |

Cr |

Ni |

P |

S |

Cu |

other |

|

|

JQ.MH00Cr21Ni10T |

0.027 |

1.75 |

0.57 |

20.27 |

9.56 |

0.023 |

0.010 |

- |

- |

Product performance

|

Compliant (equivalent) standard model |

An example of physical properties of deposited metal (with SJ601) |

||

|

GB |

AWS |

Tensile StrengthMPa |

Elongation% |

|

F308L-H00Cr21Ni10 |

ER308L |

568 |

35.5 |

Product welding reference current(AC or DC+)

|

Diameter(mm) |

¢2.5 |

¢3.2 |

¢4.0 |

¢5.0 |

|

Welding current(A) |

400-500 |

450-550 |

500-600 |

550-650 |

Product Specifications

|

Wire diameter |

¢2.5 |

¢3.2 |

¢4.0 |

¢5.0 |

|

Package weight |

25/50/100/200/250/300/350Kg/piece |

|||

Precautions for product use

1. The temperature between welds is recommended to be controlled at about 150°C. When multi-pass multi-layer welding of small and medium-sized specifications, pay attention to controlling the welding line energy.

2. The rust layer, moisture, oil, dust, etc. of the welding part must be cleaned up.

3. The flux must be baked at 300-350℃ for 2h before use.

The above suggestions are for reference only, and the actual situation shall prevail in the specific operation. If necessary, process qualification should be carried out before determining the welding plan.

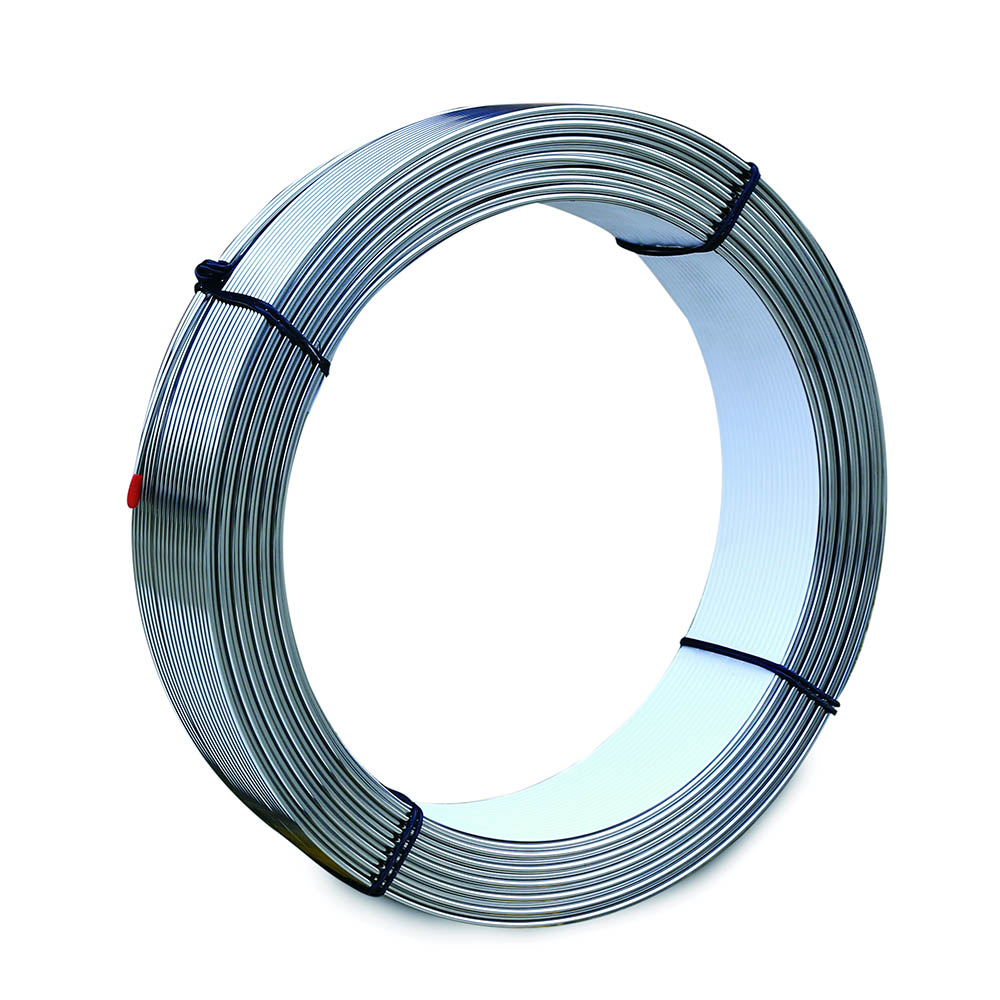

Product detail pictures:

Related Product Guide:

We have quite a few great team customers very good at internet marketing, QC, and dealing with kinds of troublesome trouble while in the output approach for Good Quality Stainless Steel Submerged-Arc Welding Wire - JQ.MH00Cr21Ni10T stainless steel submerged-arc welding wire – Jinqiao , The product will supply to all over the world, such as: Japan, Pakistan, Congo, To let customers be more confident in us and get the most comfortable service, we run our company with honesty, sincerity and best quality . We firmly believe that it is our pleasure to help customers to run their business more successfully, and that our professional advice and service can lead to more suitable choice for the customers.

The customer service staff's attitude is very sincere and the reply is timely and very detailed, this is very helpful for our deal,thank you.